Up until now I’d been using scrap bits of metal to act as clamps, holding my PCBs down to be milled:

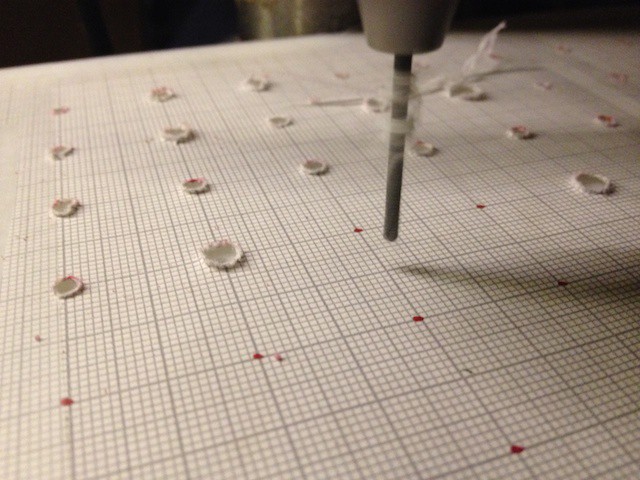

Not exactly convenient. I needed a better way to fix workpieces down for the mill to work on, but you never know what sized bits you’re going to be dealing with in future, so I thought I’d make a perforated work bed. I bought a chunk of white acetal (an engineering plastic) and stuck a bit of graph paper to it, then used it as a guide to drill holes at regular intervals.

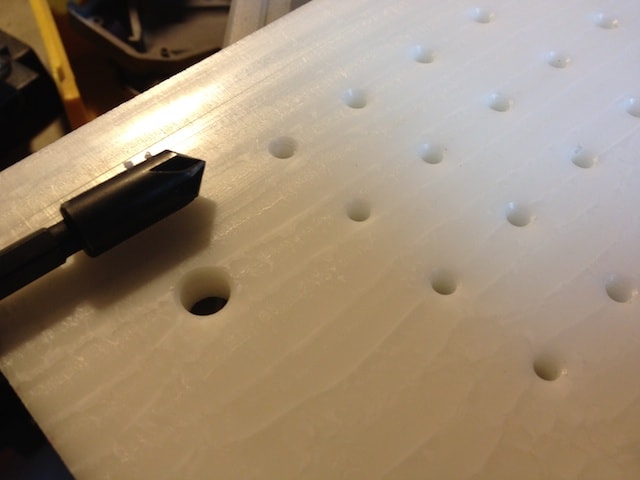

I used a countersink bit to take the sharp edges off the holes, then used an M5 tap to thread them all.

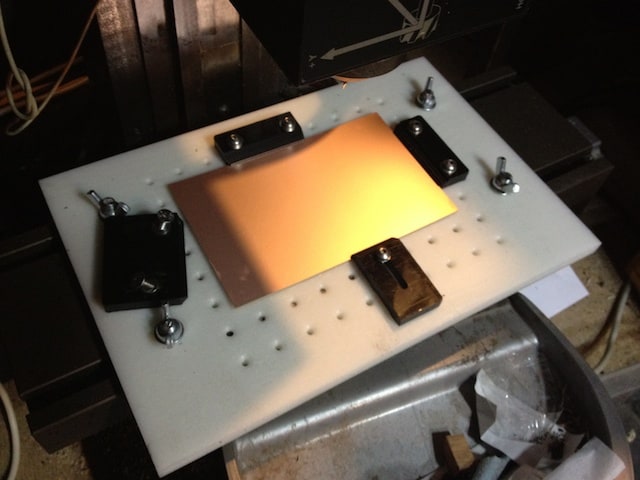

Finally, I designed some little clamps and cut them out of black acetal.

Using them I can easily clamp down just about any size of PCB to the bed for the mill to work on, plus it’s much easier to clamp other flat things down too. Here’s a bit of clear acrylic being worked on:

Total cost: just under £10 for the plastic plus a handful of M5 bolts. Nice.